Industrial robots

Industrial robots

Introduction to Industrial Robots

An industrial robot is a programmable mechanical device designed to perform complex tasks with precision and speed within various manufacturing processes. These sophisticated robots significantly increase productivity and quality while reducing operational costs.

The term "industrial robot" typically refers to robot systems capable of precise, repetitive tasks, providing reliability and accuracy unattainable by human labor alone. Their versatility makes them invaluable across diverse industries, transforming traditional workflows into highly automated processes.

Types of Industrial Robots

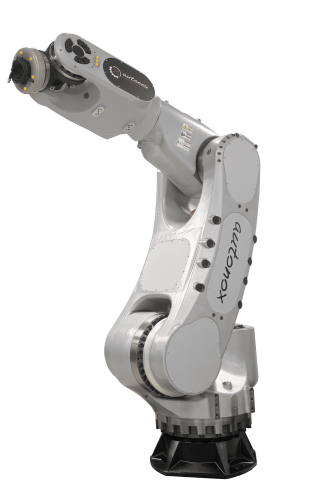

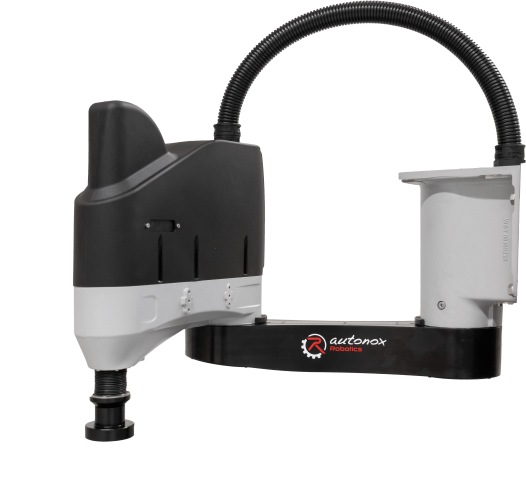

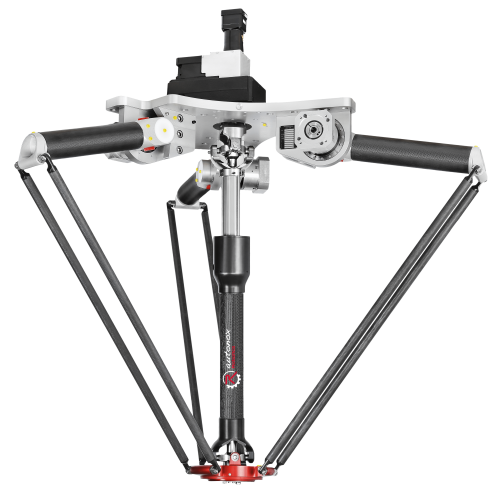

Industrial robots vary significantly in design and functionality, allowing manufacturers to select the ideal type for their specific needs. One of the most common types is the industrial robot arm, characterized by flexibility, precision, and multi-axis capabilities. Notably, industrial robot 6-axis models are highly sought-after due to their ability to maneuver seamlessly in various directions, providing exceptional dexterity and adaptability. Additionally, other types include SCARA robots, delta robots, and cartesian robots, each suited to different operational demands and spatial requirements.

Benefits of Industrial Robots

Implementing an industrial robot system offers numerous advantages for businesses aiming for competitive manufacturing. Robot industrial systems enhance productivity by operating continuously with minimal downtime, significantly outperforming human efficiency in repetitive tasks. Additionally, the precision and consistency delivered by these robotic systems drastically reduce errors and improve overall product quality.

Applications of Industrial Robots

Industrial robots serve an extensive range of applications, reshaping numerous industrial sectors. Common applications include welding, painting, assembly, packaging, and material handling. Industrial robot arms specifically excel in assembly lines and intricate manufacturing tasks requiring meticulous precision. Robot industrial technologies have notably transformed automotive manufacturing, electronics assembly, pharmaceuticals, and food production. The extensive use of these robotic solutions reflects their significant contribution toward streamlining industrial processes and achieving efficiency goals.

Key Features to Consider When Choosing an Industrial Robot

Selecting the right industrial robot involves careful consideration of several critical factors. First and foremost, assess the robot's payload capacity and reach, crucial for specific industrial applications. Additionally, the choice between a standard or industrial robot 6-axis configuration should align with the complexity and dexterity required in manufacturing processes. Evaluating the robot's accuracy, repeatability, and speed is essential to meet stringent production requirements. Businesses should also consider ease of programming, integration flexibility, and compatibility with existing industrial robot parts to ensure seamless operational efficiency.

Industrial Arm Robot Maintenance and Safety Tips

Proper maintenance and adherence to safety protocols are essential for maximizing the lifespan and effectiveness of an industrial robot arm. Regular inspections of industrial robot parts help detect and address wear and tear promptly, preventing costly downtimes. Routine maintenance, including lubrication, calibration, and cleaning, enhances robot efficiency and ensures consistent high performance. .

Ensuring compliance with safety standards is equally vital. Manufacturers and operators should implement comprehensive safety training programs, safeguard robotic workspaces, and regularly update robot programming to mitigate operational risks effectively.

Future Trends in Industrial Robots

The industrial robot manufacturing sector is witnessing significant advancements driven by innovations in technology and automation. Emerging trends highlight increased adoption of collaborative robots (cobots), designed to work safely alongside human operators, creating flexible and interactive work environments.

Developments in artificial intelligence (AI) and machine learning significantly enhance robotic capabilities, allowing for improved adaptability, self-learning, and predictive maintenance. As industrial robot manufacturers continue integrating smart technologies, businesses can expect increasingly sophisticated automation solutions that boost productivity, efficiency, and competitiveness.

Industrial Robots by autonox Robotics

autonox Robotics stands out among leading industrial robot manufacturers due to its commitment to innovative, high-quality robotic solutions. Specializing in advanced industrial robot 6-axis models, autonox Robotics provides versatile robotic systems capable of addressing complex industrial tasks with remarkable efficiency.

Their comprehensive range of industrial robot parts and reliable support infrastructure underscore autonox Robotics’ dedication to superior customer service and technical excellence. By consistently prioritizing innovation and quality, autonox Robotics significantly contributes to the evolution and advancement of modern industrial automation.