Robot arms from the Ortenau region

In our “From the Southwest” section, we present products that are known beyond the region's borders, but which few people know are produced locally. This time: controller-independent robot arms from autonox Robotics GmbH in Willstätt.

Mechanics for Industry 4.0

Industry 4.0, the intelligent networking of machines and processes, is part of our working world. From packaging to cleaning, robots are taking over difficult or monotonous tasks in many areas. But what use are the smartest controls or the smartest computer system if the mechanics to execute them are missing? This is precisely what Hartmut Ilch thought when he became the sole shareholder of Autonox Robotics GmbH ( www.autonox.com) in 2019. The company is located in the Willstätter Industriepark on the former BASF site. His business strategy: “We don't sell a bit of software. We don't sell a bit of electronics. We only sell mechanics. Just like 120 years ago, when they built trains. And it works.” Klaus Deutscher is the co-managing director responsible for Autonox's business affairs. ‘I am actually a jack of all trades here,’ says the former banker with a wink. He keeps an eye on the financial and legal aspects while the engineers tinker and invent.

Quick-change artist

Autonox Robotics specializes in the development and production of modular robot mechanics. Articulated robots can move almost without restriction in three-dimensional space. This is possible thanks to the joints that connect the robot arms. Two to six axes, known as degrees of freedom, allow a greater or lesser degree of mobility. Depending on the customer's requirements, the weight to be carried or the distance the robot arm has to travel, the engineers develop the individual equipment from the existing modules: “If, for example, the front axis is needed 20 centimeters longer, the construction is changed and recalculated there,” explains Klaus Deutscher. “Then, if the material is not there, it is ordered – keeping large stocks is limited due to the countless variants.” If everything is there, the complete robot mechanics are assembled on site in Willstätt and a test run of about twelve hours follows before the whole thing goes to the customer – usually these are machine builders who are completing a complete automation for their end customer.

In use across all industries

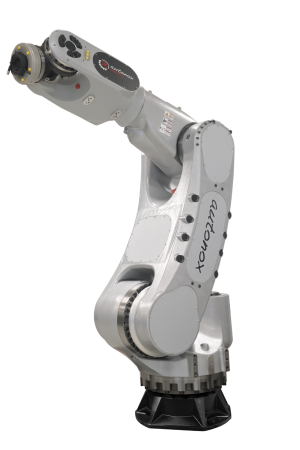

Six-packs of PET bottles, which arrive at the grocery store on pallets, slices of cheese that go from the package to the bread roll in the morning, or coffee capsules for breakfast coffee – the chances are good that at some point in the run-up to the tasting, a robot mechanism from Autonox Robotics was involved. From the pharmaceutical to the food industry, from the cosmetics to the automotive industry: companies worldwide use the mechanisms for packaging, palletizing, portioning, for logistics, for loading and unloading, and also for testing and measuring. The material and coating vary depending on where the mechanisms are used. “A robot that is to be used in meat processing, for example, must be able to withstand the harshest cleaning agents and also very high temperatures. It has to be equipped accordingly – right down to the seals,” explains Deutscher. The company's latest development is the articulated arm “articc.m6-2390-150kg” (picture), which weighs a ton itself and is a real heavyweight. “It can handle up to 150 kilograms, is equipped with six degrees of freedom and works particularly precisely thanks to its high rigidity,” says Klaus Deutscher.

A tinkerer by passion

Over time, Autonox Robotics has registered numerous patents, and in total the company sells 1,200 of its robot mechanisms worldwide every year. The company, which employs 66 people, has grown enormously in recent years, and a growth in sales of more than 40 percent is also expected this year. Three years ago, the company also established Autonox Robotics LLC in Atlanta, Georgia (USA) together with Edgar Bechtle, a friend from university in Offenburg, in order to tap into the North American market. It is clear that the two managing directors are passionate about what they do: “We are still growing. Not only because we were there with the right product at the right time, but also because I have a few crazy people here – and I'm one of them – who are simply absolutely passionate about mechanics,” says Hartmut Ilch, getting to the heart of the matter. And he wants more: ‘You can always do better, because there's always room for improvement.’ Andrea Keller