From powerful articulated robots to high-speed delta kinematics, autonox Robotics offers a broad portfolio of controller-independent robot mechanics for precise, customer-specific solutions. This even makes it possible to mill tempered steel—something previously considered impossible. The diversity is based on partnerships with control and drive technology providers and is complemented by regional manufacturing in the Black Forest—ensuring short supply chains and quality made in Germany.

Integrating robots into existing production lines is often complex, costly, and fraught with technical challenges. Beyond the required space, systems must seamlessly fit into the production environment - yet manufacturer-specific robot controllers are difficult to couple with machine controls. Interfaces may allow programming of movements and processes via higher-level controllers, but the internal motion logic often remains inconsistent and hard to adjust externally. As a result, external interventions to optimize motion and process flows are only possible to a limited extent.

“This is exactly where we come in,” says Hartmut Ilch, Managing Director at autonox Robotics. Under the motto ‘Better Robotics in Components’, the company from Willstaett in Baden-Wuerttemberg offers controller-independent robot mechanics that adapt flexibly to the production environment—not the other way around. By eliminating control interfaces, robots and machines merge into a single unit.

Open solution

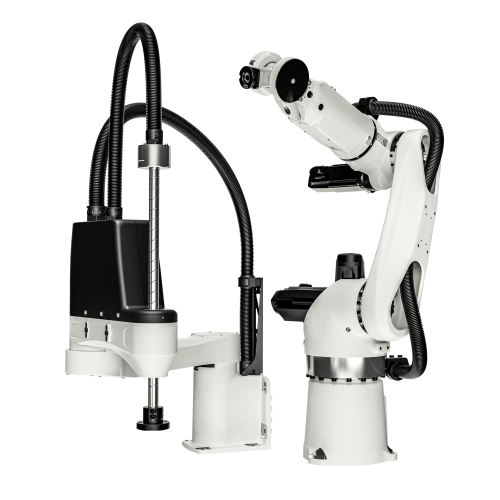

autonox supplies the mechanics as an automation component. Drive technology, controllers, and software are not included. The range of available robot mechanics includes heavy-duty articulated robots and ultra-fast delta kinematics - each with different payloads, degrees of freedom, and configurations, for example for palletizing, steel milling, or hygienic food processing.

Machine builders can combine numerous robot mechanics with various drive and control components from major automation providers to create the perfect solution - delivering significantly better robotics compared to a closed standard system. “Users benefit from a highly integrated, autonomous system with just one controller that reliably handles even complex tasks,” explains Clemens Ratajczak, Operations Manager at autonox. “This puts us one step ahead of major robotics manufacturers with their standardized controllers and solutions.” These often cannot be easily connected to machine controls. As a small, agile company with an extensive portfolio of controller-independent mechanics, autonox can respond very specifically to customers’ individual requirements.

Integration without compromise

In close development partnership with Trumpf, autonox implemented a precise, customer-tailored robotic mechanics solution for the TruBend Cell 7000 bending automation system, which produces small parts highly autonomously and efficiently. “The goal was maximum productivity with very high accuracy,” says Ratajczak. The challenges: exact positioning of the kinematics, precise specification of robot geometry regarding space and reach, and an especially robust wrist axis. “We delivered a process-specific articulated robot and a sCara robot. Due to accuracy requirements, each articulated robot is geometrically measured. In addition, a stable wrist axis ensures robustness for the process.”

Customers benefit from a fully customized solution: unified hardware for machine and robot, a single user interface, and seamless integration into the existing control system. Excellent collaboration was a key success factor in developing a highly autonomous, productive, and user-friendly solution tailored to operators’ needs.

Milling tempered steel with robots

For a long time, milling tempered steel with a robot was considered impossible. “At Automatica in Munich, we showcased a new solution that enables highly precise machining of very large and long components - even in demanding industries such as aerospace,” reports Ilch. “To achieve this, we consistently advanced our robot mechanics and worked closely with Siemens and Fraunhofer IFAM in Stade.” The result: a highly rigid robot mechanics with extremely precise motion behavior, suitable for applications requiring high cutting forces and large volumes.

“The design includes double-supported axes and large high-precision gearboxes,” explains Ratajczak. The system uses Siemens Sinumerik One control. With the Run MyRobot/Machining option, the robot can be programmed like a conventional CNC milling machine using G-code. The mechanics are designed to minimize interference contours and maximize collision safety. Milling parameters remain constant regardless of the robot’s pose, providing great flexibility - no re-clamping required. For very long components, the solution can be mounted on a linear axis as a seventh axis, enabling machining lengths of 10 meters or more. “Compared to traditional machine tools, the robotic solution is far more location-flexible, compact, and cost-effective - especially for very large structures or confined production environments,” emphasizes Ilch.

By fully integrating the milling robot mechanics into the CNC control, robots can now perform not only handling tasks but also preparatory, value-adding machining steps such as roughing - reducing expensive machine runtime. At the same time, efficiency, flexibility, and value creation across the entire production process increase. The close integration of robot mechanics and CNC control opens new possibilities for automated machining.

Perfectly aligned

The TruBend Cell 7000 and CNC-enabled milling robotics demonstrate how precisely tuned mechanical solutions push the boundaries of traditional automation. Whether highly productive bending of small sheet metal parts or demanding machining of hardened steels - the close collaboration between autonox and partners like Trumpf and Siemens, combined with continuous advancement of proprietary technologies, enables solutions that set new technical and economic benchmarks. The result: highly flexible, robust, and user-friendly systems that integrate seamlessly into modern production environments and pave the way for the next generation of industrial automation.

autonox focuses on controller independence with a clearly defined mechanical interface. The broad range of mechanics, from two to six axes and payloads from 0.5 to 850 kg, allows application-specific solutions without platform constraints. Digital tools such as the autonox Finder and autonox Simulator accelerate selection, machine design, and virtual commissioning.

“One more thing is particularly important to us,” says Ilch. “We deliberately rely on manufacturers and suppliers from the region - specifically from the Black Forest. This ensures short coordination paths, guarantees high quality made in Germany, and contributes to sustainable sourcing through reduced transport routes. That’s real added value for our customers.”