Parallel Kinematics Robots

Parallel Kinematics Robots

Introduction to Parallel Kinematics Robots

Parallel kinematic robots useparallel moving kinematic arms to move the end effector. With actuators fixed at the base, this closed structure of parallel mechanism kinematics ensures precise and synchronized control. A parallel working Robot mechanic combines high stiffness with low moving mass, enabling speed and dynamics.

Unlike serial robots, where motion passes link by link, the kinematics of serial and parallel robots show that parallel designs deliver higher accuracy and efficiency. Advanced concepts such as 6 axis parallel kinematics, parallel robot kinematics, hexapod parallel robot kinematics, and kinematics of parallel manipulators demonstrate the flexibility of these systems. Special solutions like parallel SCARA kinematics or parallel robot inverse kinematics further extend their use in precision automation.

Working Principle of Parallel Robot mechanics

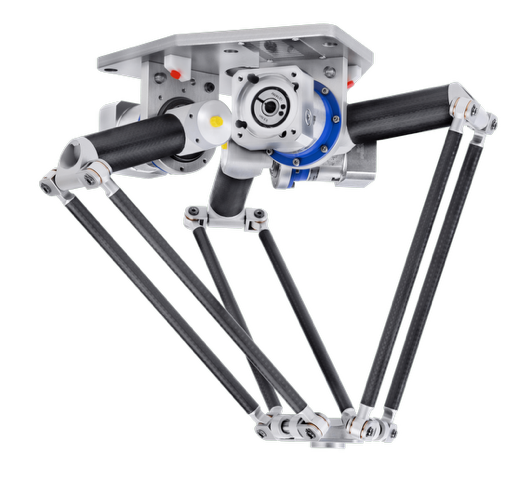

The working principle of parallel Robot mechanics is based on parallel working actuator Arms that are connected to a fixed base. Unlike serial robots, where motion is transferred link by link, a parallel kinematic distributes forces simultaneously through all Arms. This closed structure provides high stiffness, low moving mass, and synchronized motion control.

Lightweight arms, frequently made of carbon fiber or aluminum, are driven by actuators located at the case to minimize moving mass.Precise motion requires solving parallel robot inverse kinematics, calculating joint positions in real time to ensure accuracy and repeatability.

Thanks to this principle, parallel robot kinematics achieve exceptional speed, precision, and dynamic performance. These characteristics make them ideal for high-throughput applications such as pick-and-place, assembly, and quality inspection in modern automation.

Advantages of Parallel robot mechanics

Parallel robot mechanics, especially Delta robot kinematics, offer significant advantages in comparison to serial structures. With actuators fixed at the base, the Delta robot design reduces moving mass, enabling extremely high accelerations and short cycle times for modern high-speed applications. The closed structure provides high stiffness and minimizes deflections or vibrations, while the mostly symmetric architecture ensures even force distribution for optimized positioning and efficiency.

By precisely coordinating multiple parallel arms, Delta robots guide the end effector quickly and accurately within the workspace. This results in outstanding dynamics combined with a compact design, making parallel robot mechanics ideal for applications requiring speed, precision, and efficiency.

Applications of Parallel Robot mechanics

Parallel robot mechanics are indispensable in modern industrial automation, where speed, cycle time, and dynamics are critical. Their compact design and low moving mass make them ideal for high-performance production processes.

In packaging, they handle sorting, grouping, and packing tasks at very high cycle rates. With pick-on-the-fly capability, they can capture and place moving products, making them perfect for continuous production lines. In food processing,parallel Robot mechanics or better known as DELTA Robots ensure fast and hygienic handling, with models designed for washdown and clean environments.

The pharmaceutical industry benefits from their repeatability and ability to operate in cleanrooms, for filling, packaging, inspection, and micro-assembly. In electronics, parallel robot kinematics support precise placement of sensitive components, PCB assembly, and automated testing, often combined with vision systems and inline quality control.

Further applications include laboratory automation, medical technology, 3D printing, battery production, and logistics, where their speed and precision enable dynamic sorting. With modular design, high efficiency, and easy integration, parallel robots kinematics provide a future-proof solution for advanced automation.

Types of Parallel Kinematics Robots

There are several types of parallel robots, each designed to meet specific industrial requirements for speed, precision, and flexibility. One of the most common is the Delta robot kinematics, widely used in high-speed pick-and-place applications thanks to its lightweight arms and closed structure, which ensure low moving mass and high stiffness.

Another important category is the hexapod parallel robot kinematics, which provides six degrees of freedom. These systems are ideal for applications requiring complex positioning and orientation, such as machining, metrology, and advanced assembly. Their architecture allows precise control of both translational and rotational movements.

Specialized solutions include parallel SCARA robots, which combine the advantages of parallel structures with the familiar SCARA layout, offering compactness and speed for tasks like assembly and handling. In addition, hybrid systems and modular platforms expand the field, enabling tailored solutions that integrate seamlessly into modern automation processes.

Overall, the diversity in parallel robot kinematics ensures that companies can select the optimal configuration for their specific application, from high-speed packaging lines to precision manufacturing and laboratory automation.

Comparison with Serial Robots

When comparing parallel robots with serial robots, the fundamental difference is located in the structure of motion transfer. With serial robot mechanics,, the end effector is moved step by step through a chain of links and joints, which often leads to higher moving mass and reduced stiffness. By contrast, a parallel kinematic machine distributes forces simultaneously across several kinematic chains connected to a fixed base.

This architecture results in lower inertia, higher mechanical stiffness, and synchronized control of all degrees of freedom. As a consequence, parallel robot kinematics enable faster cycle times, higher precision, and improved repeatability. Serial robots like 6-Axis robots, however, typically offer a larger workspace and simpler control models, making them more suitable for tasks requiring wide reach rather than maximum dynamics.

Overall, the kinematics of serial and parallel robots highlight complementary strengths: serial designs excel in versatility and reach, while parallel structures dominate in speed, stiffness, and accuracy for demanding industrial automation.

Future Developments in Parallel Robot Kinematics

Parallel robots, especially Delta robot kinematics, are becoming increasingly important in industrial automation. Continuous advances in mechanics, control, and software integration drive higher precision, shorter cycle times, and greater flexibility. Future systems will stand out through efficiency, adaptability, and seamless integration into modern production.

Key developments include intelligent sensors and AI-based control algorithms, enabling adaptive motion and real-time quality assurance. Miniaturized designs with higher payload capacity open new fields in medical technology, micromounting, and laboratory automation. At the same time, robust and hygienic designs expand use in food and pharmaceutical production.

Another major trend is simplified commissioning and programming. With modern engineering tools, digital twins, and browser-based interfaces, even complex parallel kinematic machines can be set up quickly and intuitively. Combined with vision systems, IIoT, and cloud-based analytics, parallel robot kinematics will play a central role in smart, connected manufacturing. Their dynamics, energy efficiency, and precise motion control position them as a key technology for the next generation of production.

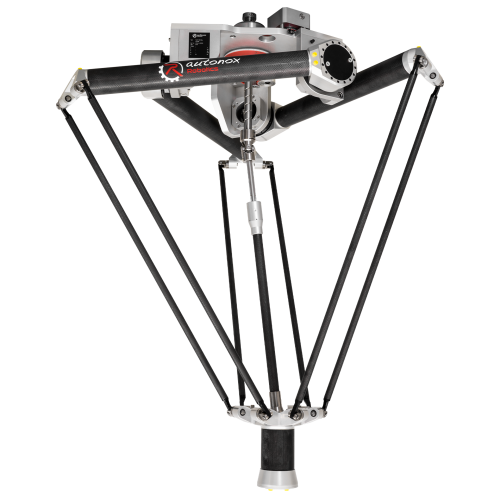

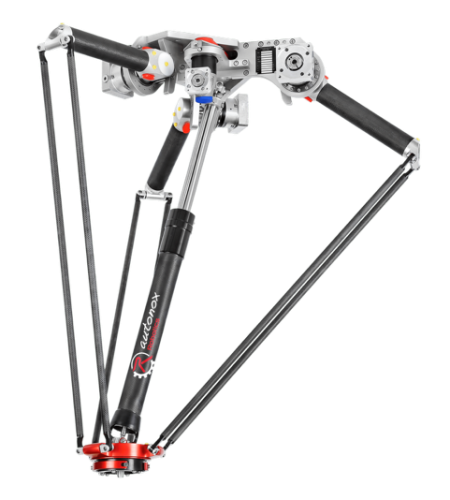

Parallel Robot mechanics from autonox Robotics

autonox Robotics offers a comprehensive portfolio of parallel Robot kinematic designed for maximum speed, precision, and reliability. Our Delta robot mechanics are built with robust, industry-grade construction, ensuring high dynamics, minimal moving mass, and low maintenance. All systems are engineered, manufactured, and quality-tested in Germany, guaranteeing long service life and maximum process safety.

With standardized interfaces and a high Variety of different Robot mechanics, our systems can be integrated easily into diverse automation environments. Whether for pick-and-place, sorting, dosing, or precise assembly and inspection tasks – the parallel Robot mechanics from autonox provide the ideal combination of dynamics, accuracy, and flexibility. Their well-engineered design and high adaptability contribute to sustainable efficiency gains in modern manufacturing.